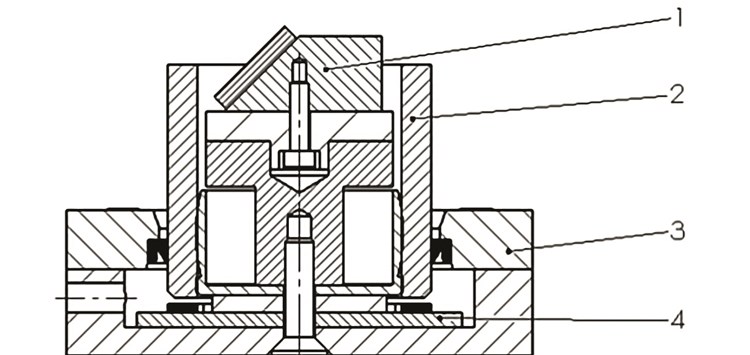

Optical measurement of contact width 1: Mirror with holder, 2: Transparent tube, 3: Housing, 4: Board with LED [1] (Bild: R. Teichert: Tribologie von fettgeschmierten Radialwellendichtungen. Dissertation am 23.09.2022,TU Bergakademie Freiberg, 2022. )

24.10.2023 Scaling of radial seals

Safely go into series production

Standard seals are required in almost all conceivable machine solutions for common nominal diameters. A common practice here is to transfer an initial original design of one diameter to a large number of other diameters. In this way, the seal manufacturers can implement an adapted scaling of the series, which ensures the safe function of the individual size.

This work investigates radial shaft seals in three dimensions to check the different designs. Differences in the contact size and the radial load are observed. On the experimental side, oil and grease lubrication has been investigated. For the investigated seal type differences in the friction characteristic are observed. Seals are available in various designs and in many sizes adapted to the nominaldiameter. In addition, there are many variants for the outer diameter and the width of the seal. Therefore, the standard seals must be designed in many different sizes.