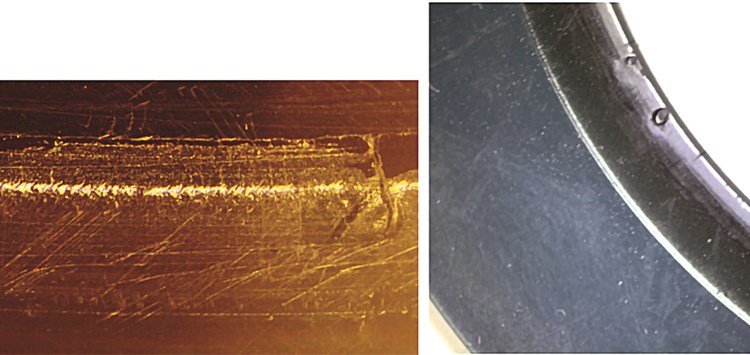

Blisters, cracks and discoloration of the NBR sample after test (Bild:MEGT, Rheinland-Pfälzische Technische Universität Kaiserslautern-Landau )

24.10.2023 Cost-efficient evaluation of rubber-lubricant incompatibility

With the focus on tribological loads that correspond to rotary shaft seals

In a sealing system, the compatibility between the rubber and the lubricant is essential for the long term reliability. Incompatibility can lead to damage to the seal and thus to unwanted leakage or even failure of the sealing system due to changes in the rubber. These can manifest themselves through various mechanisms.

The currently available tests are either very unspecific for the conditions in a sealing contact and also have a bad reproducibility (static tests) or are very costly and cannot be performed in early stages of lubricant development, where only a small lab sample is available. The development of a new dynamic test on a simple tribometer would make it possible to perform compatibility tests for systems with tribological contact.Chemical interactions between the lubricant and the rubber cause irreversible changes in the rubber properties. This can afflict the inter molecular cross-linking either through a dissolution of network nodes (hydrolysis) or a postcuring, which affects mechanical properties of the rubber, such as the hardness or the elasticity, and thus changes the seal behavior [1, 2].