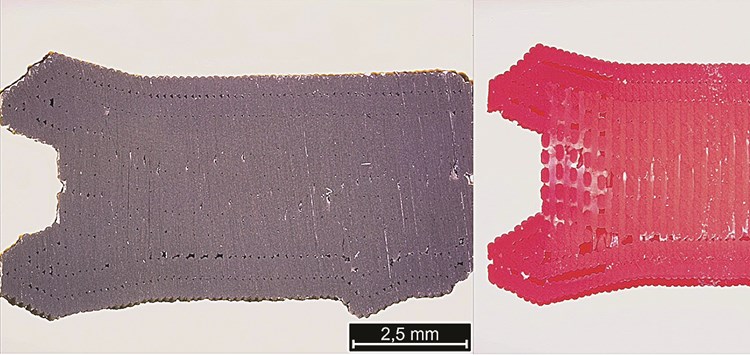

Sample parts cross section (Left: filament 9; Right: filament 1) (Bild: University of Applied Sciences Hochschule Emden/Leer)

24.10.2023 Towards additively manufactured dynamic rod seals

Investigating the suitability of additive manufacturing methods and materials

In a recently started DFG-funded research project a range of methods was defined, which shall be considered in the next phases of the project. For one of those methods, Fused Filament Fabrication (FFF), commercially available TPU-materials were analyzed. A set of potential materials has been defined and analyzed with respect to different criteria. These criteria comprise the processability, the static stiffness of the material, and the tribological properties. In a systematic process, the capability of the materials has been evaluated and compared with a commercially available reference sealing material to find the most promising approaches. With these findings, a fully coupled FSI (fluid-structure interaction) simulation model was developed and parametrized to predict the behavior of 3D-printed seals under working conditions.

In recent years, additive manufacturing (AM) technologies have massively developed and found more and more application in different fields of constructive engineering. To date, only a few tests have been performed to use additive manufacturing technologies for producing seals. Seals from conventional production are not “expensive” parts, but they exist in an enormous number of geometry variants and have, in parts, delivery times of several weeks. This forces appliers of sealings to well organize their spare-part storage in order to avoid costly machine standstill. This problem increases if the region of machine application is not well connected to the traffic net, as this might be the case in the drilling industry, the offshore wind industry, or on polar stations. To go around this dilemma, few systems are available to produce seals locally and on-demand, e.g. [1]. These systems rely on a highly automated and user-friendly chipping machine that cuts seals of different geometries from semi-finished material in stock.