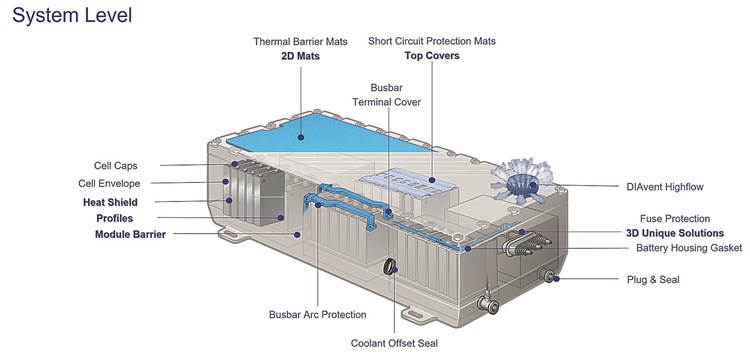

Battery components currently addressed on battery system level [5] (Bild:Freudenberg FST GmbH (07/2023), Products overview Thermal Barriers)

31.10.2024 Testing Thermal Barriers for Lithium-Ion Batteries

A short overview of the application field, example battery components and connected test sets

Transformation of automotive industry from internal combustion engine (ICE) to electric vehicles (EV) is already in progress and taking up speed. Additionally increasing battery and cell energy density levels as well

as faster charging rates lead to increased demands for thermal management of batteries as well as materials and components used in order to mitigate the result of thermal runaway events and to prevent thermal propagation. In some cases, known test methods can be used for material and component development whereas in other applications adaptions have to be made to existing methods. However, there is also a new class of tests not common to the automotive industry dealing with direct exposure to flames and hot particles.

These tests made some progress in the past but still need improvement in terms of repeatability and standardization.

The e-mobility market has been growing continuously for over a decade. As can be seen in [1] growth was relatively small in absolute terms, compared to around 85 million vehicles produced worldwide in 2022[1, 2]. However, Fig.1 also shows that since 2020 at the latest the annual increase in electric vehicles (EV) has reached an almost exponential growth curve. This sharp increase was mainly triggered by national and international regulations limiting future CO2 emissions from vehicles or even an outright ban on the internal combustion engine (ICE). [1]